Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Have you ever stared at a plastic sheet or a display and been blinded by that annoying glare from lights or the sun? It's frustrating, right? Like trying to read a book under a spotlight that just won't quit. Well, that's where special coatings come in handy. Here is a diving deep into the world of anti-glare and anti-reflective coatings on plastic sheets. These aren't just fancy add-ons; they're game-changers for visibility and usability. Let's break it down step by step, like chatting over coffee about something that actually matters for your eyes and your wallet.

Picture this: You're installing a new protective cover for your artwork or setting up a display board outside. The last thing you want is reflections ruining the view. Coatings like anti-glare and anti-reflective are designed to tackle those pesky light bounces. But they're not the same beast. Anti-glare is like putting a frosted filter on a window—it softens the harshness. Anti-reflective, on the other hand, is more like magic that makes reflections disappear almost entirely. Understanding these can save you time, money, and headaches. Plastic sheets, made from materials like acrylic or polycarbonate, are super versatile, but without the right coating, they're prone to glare issues. So, why bother? Because in a world full of bright lights and screens, clear vision is king.

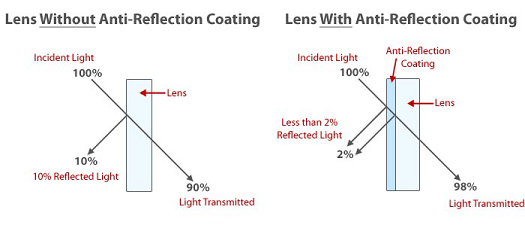

Think about it—have you noticed how your phone screen gets unreadable in direct sunlight? That's glare at work, reflecting light right back at you and obscuring what's underneath. On plastic sheets, this problem amplifies, especially in larger surfaces like windows, signs, or protective barriers. Special coatings reduce eye strain, improve safety (like in driving visors), and enhance aesthetics. They're not just for eyeglasses anymore; industries from art to automotive rely on them. Without coatings, up to 8-10% of light can reflect off plain plastic, dimming what you see. Coatings boost transmission to over 99%, making everything sharper. It's like upgrading from a blurry photo to high-definition—suddenly, details pop.

Plastic sheets pop up everywhere, don't they? From greenhouse panels that need to let light in without blinding glare, to museum displays protecting artifacts while keeping them visible. In homes, they're in picture frames or shower doors. Commercially, think retail signs or machine guards. Each use demands different light handling—outdoor ones battle sun rays, indoor ones fight artificial lights. Coatings tailor these sheets to perform better, extending their life and usability. If you're DIY-ing a project, knowing coatings can turn a basic sheet into a pro-level piece.

Alright, let's zoom in on anti-glare first. It's the more straightforward option, often what people grab for quick fixes. Imagine spreading butter on bread—it smooths things out but adds a matte texture. Anti-glare does something similar to plastic surfaces.

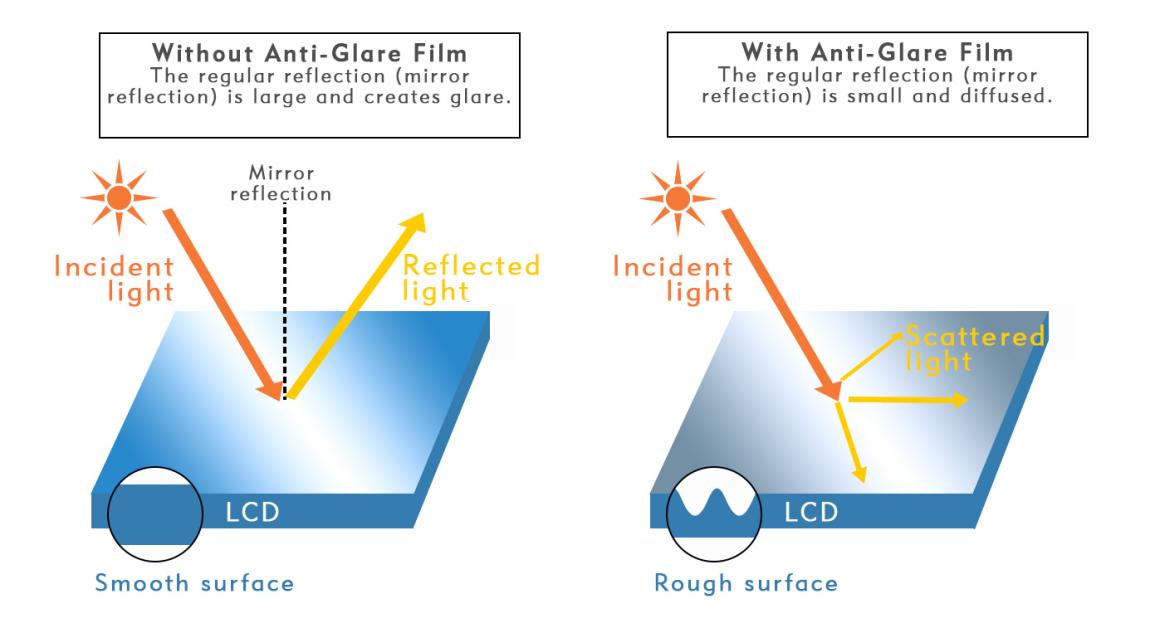

Anti-glare coating, sometimes called non-glare or matte finish, is a treatment applied to plastic sheets to diffuse incoming light. It's not about eliminating reflections entirely but scattering them so they're less intense. You'll see this on computer monitors or TV screens where bright room lights could otherwise create hotspots. For plastic sheets, it's etched or sprayed on, creating a rough surface that's visible as a subtle frostiness. It's popular because it's affordable and effective in many scenarios, like outdoor signage where sun glare is the enemy.

Here's the cool part: Anti-glare works by roughening the surface at a microscopic level. When light hits, instead of bouncing back like a mirror (specular reflection), it scatters in all directions (diffuse reflection). Think of a calm lake versus a choppy sea—the calm one reflects clearly, the choppy one breaks up the image. This scattering reduces the glare's brightness, making it easier on your eyes. On plastic, this is often done via chemical etching or adding particles during manufacturing. It's simple physics, but it makes a world of difference in high-light environments.

Why choose anti-glare? For starters, it's budget-friendly—often half the cost of its counterpart. It excels in outdoor settings, battling direct sunlight without much fuss. Plus, it hides fingerprints and smudges better than glossy surfaces. If you're framing art, anti-glare prevents that mirror-effect where you see yourself instead of the painting. It also reduces eye fatigue during long exposures, like in office dividers or vehicle windows. In bursty terms, it's like a reliable old friend—always there when lights get too rowdy.

But hey, nothing's perfect. Anti-glare can slightly blur the view underneath because it diffuses outgoing light too. Up close, you might notice a hazy effect, reducing sharpness. It's also prone to dirt buildup in those rough textures, making cleaning a chore. On larger plastic sheets, this haze can be more noticeable, so it's not ideal for precision viewing like medical displays. If clarity is your top priority, this might not cut it.

Now, shift gears to anti-reflective, or AR coating. This one's the high-tech sibling, using clever tricks to zap reflections away.

Anti-reflective coating is a thin, multi-layered film applied to plastic sheets to minimize light reflection. Unlike anti-glare's matte look, AR is nearly invisible, often with a faint blue or green tint. It's common on camera lenses or high-end eyeglasses, but for plastic sheets, it's a boon for displays needing crystal-clear views. It boosts light transmission, letting more through while reflections drop to under 1%.

Get ready for some metaphor magic: AR works like noise-canceling headphones for light. Layers of materials with varying refractive indices create destructive interference—waves of reflected light cancel each other out. Applied via vacuum deposition, it's precise and durable on plastics like polycarbonate. Imagine two waves crashing and nullifying; that's AR in action. This doesn't scatter; it reduces reflection amount, preserving sharpness.

AR shines in indoor setups, reducing glare from screens or lights without haze. For plastic sheets in electronics or art, it enhances colors and contrast—think vibrant photos without distractions. It's great for night use, cutting headlight glare on visors. Plus, it makes sheets look premium, almost invisible. In terms of perplexity, it's the sophisticated choice for when you need every detail crisp.

On the flip side, AR costs more due to complex application. It can scratch easier if not top-quality, and that tint might not appeal to all. Cleaning requires care to avoid damaging layers. For super-bright outdoors, it might not diffuse as well as anti-glare, though it still outperforms plain plastic.

Time for the showdown. Let's pit them against each other in key areas.

Anti-glare scatters light like confetti at a party—fun but messy. AR cancels it like a pro editor cutting flaws. Functionality-wise, anti-glare handles external bright sources better by diffusion, while AR excels at overall reflection reduction, boosting transmission.

Clarity? AR wins hands down—no haze, sharper images. Anti-glare trades some sharpness for glare reduction. For close-up work on plastic sheets, AR feels like HD; anti-glare like standard def.

Anti-glare is cheaper and easier to apply, often during sheet manufacturing. AR requires specialized vacuum processes, hiking the price. For bulk plastic, anti-glare saves cash; for premium, AR justifies the spend.

Durability edges to anti-glare—its rough surface hides scratches better. AR needs gentle handling but repels dirt with hydrophobic layers. Maintenance: Both need microfiber cloths, but AR stays cleaner longer.

Anti-glare looks matte and frosted, hiding imperfections. AR is glossy yet non-reflective, making plastic seem clearer and more professional. Choose based on if you want subtle or sleek.

Where do these coatings fit in your world? Let's explore.

In monitors or touchscreens made from plastic, anti-glare suits bright offices, reducing overhead light glare. AR is perfect for high-res displays, like medical imaging, where every pixel counts without distortion.

Framing pros love anti-glare for diffusing gallery lights, preventing viewer reflections. AR takes it up a notch for museums, offering invisible protection that lets art shine true.

Outdoors, anti-glare on greenhouse plastic cuts sun glare while letting light in. Industrial shields use AR for machinery views, ensuring safety without visual interference.

In cars, AR on dashboards reduces night glare; anti-glare on windshields handles sun. Marine uses favor AR for salt-resistant clarity on boat panels.

Stuck deciding? Here's help.

Environment: Bright outdoors? Anti-glare. Indoor precision? AR. Budget: Tight? Anti-glare. Usage: Frequent cleaning? AR's easier. Material: Thicker plastics suit AR better.

Experts say test samples—hold them under lights. Consider combos for hybrid benefits. Always check warranties for durability.

Keep them pristine with these.

Do: Use microfiber and mild soap. Don't: Abrasive cloths or chemicals. Rinse first to avoid scratches.

Store away from dust, avoid extreme heat. Reapply if possible, or protect with cases.

So, wrapping up, anti-glare and anti-reflective coatings each have their spotlight on plastic sheets. Anti-glare diffuses for affordability and outdoor prowess; AR cancels for supreme clarity and versatility. Pick based on your scenario—maybe even try both. Your eyes will thank you. What's your next project? Drop a thought below!

7 Very Important Coatings on Polycarbonate Sheet You Should Know

Top 10 Polycarbonate Fabrication and Machining Solution Suppliers You Should Know

Guidance to Know the Difference Between Anti-Glare and Anti-Reflective Coating on Plastic Sheets

Ice Rink Shields: Boosting Safety for Players And Spectators

The Shift To Acrylic And Polycarbonate: Why Ice Rinks Are Upgrading Their Shields

Contact Us